|

CAMS & VALVE TRAIN

For Sportster & Buell

|

Quick Links:

|

XL Cams

Proper cam selection is critical to the performance of your XL engine. At HAMMER PERFORMANCE we have many years experience building XL engines and we've

used literally every XL cam available at one time or another. We're proud to offer on this page the grinds that we've had the best success with, and that

work the best with our head work.

Here's a quick guide for cam selection. The first spec to look at when selecting your cams is the intake close timing. What happens is that the piston is well on it's way

up on the compression stroke before the intake valve closes. This is done to maximize cylinder fill, as the incoming fuel has inertia and the cylinder continues to fill for a

little while even after the piston has started coming up. But the amount of time the cylinder fills stays pretty constant regardless of the rpm of the engine. So as the engine

turns higher and higher rpm's, ideally you'd like to move the intake close timing out farther and farther. Since these motors don't have variable valve timing, you have to pick

an intake close timing event based on the rpm that matters most to you. Street grinds typically close the intake valve anywhere from 35 to 55 degrees after bottom dead center (ABDC)

Race grinds tend to close it anywhere from 55 to 70 degrees ABDC.

One other note on intake close timing: the later you close it, the higher compression ratio you need, since no compression takes place until the valve

is closed. A high compression ratio with early intake close timing is a recipe for detonation. Likewise a low compression ratio with late intake close timing will sap power, especially on

the bottom end. Download a copy of our Static and Corrected Compression Ratio Calculator to help decide how much compression you need with a specific set of cams.

The next important spec to look at is the overlap. Overlap is the sum of two of the timing numbers, exhaust close and intake open. Add these two numbers together. Overlap

is the number of crankshaft degrees in which both valves are open at the same time. Why is this so critical? It happens as the exhaust cycle is finishing and the intake cycle

is beginning, with the piston passing through top dead center. While both valves are open, the exhaust and intake are effectively connected together. If the exhaust pulls right then,

it'll get the next intake charge moving before the piston even starts pulling on it, giving the cylinder fill a huge head start. But if the exhaust pushes back right then,

it really messes up the cylinder fill and fuel mixture (we call it a "reversion"). So in a nutshell, more overlap turns over more control of your engine's powerband to the

pipe. When using cams with a lot of overlap, your torque curve will essentially be a map of how the pipe behaves at different rpm's. Overlap with a good pipe really helps you.

Overlap with a bad pipe really hurts you. If you've got a pipe with the sound or looks that you like, but it doesn't work well at the rpm you like to ride, choose cams with

less overlap.

TDC lift figures are also very important, and closely related to overlap. These numbers tell how much the valves are open as the piston passes through top dead center

during the overlap period. Why is this important? In a word, clearance. Contrary to popular misconception, valve to piston clearance has nothing to do with maximum lift,

because maximum lift always occurs with the piston well down the bore. It's the valve lift as the piston passes through TDC on overlap that creates clearance problems.

So if you're looking at cams with high TDC lift figures, plan on claying your motor to check your clearance. High TDC lift figures can also cause issues with valve to

valve clearance, but if we set up your heads and you told us what cams you're using, we've checked it and set it for you.

Maximum valve lift should be chosen with an eye on the

head's flow numbers. Many stock ports will "nose over",

flow-wise, at lifts well under .500". That means the port is

flowing all it can, and opening the valve farther doesn't

make it flow more. After the heads have been properly

prepared, however, this changes dramatically. So consult

your head porter about how much lift your heads can make use

of. If you're using stock heads, there's really not much

point in going past about .500 lift with even the best

factory heads.

One more point to consider: high maximum lift doesn't cause issues with valve to piston clearance, but there are a host of other clearance issues it can cause. With a high

lift cam grind, the cam lobes may want to contact the underside of the tappet bosses

and/or the pinion race, the tappets may want to run into their anti-rotation pins, rocker arms may want to

contact the rocker box tops, springs may bottom out and bind, or your retainers might run into your valve guide seals. On top of that, high lifts put a lot of side loading

on the valves which causes guide wear. The bottom line is

that there's no benefit and many drawbacks to running more

lift than your heads can make use of.

At HAMMER PERFORMANCE, we carry XL Cams from

HAMMER Performance, Andrews, Feuling and Red Shift.

- HAMMER Jackhammer 570 - Bolt-in grind for 2004-up 1200 models. Designed to give a boost in mid range and top end over the factory "W" cams with no loss in bottom end power.

Ideal for the stock 9.7:1 compression ratio but can be used up to 10:1 with careful tuning. Also works well on SMASH prepared 883 heads. Smaller than stock base circle to simplify installation. Not compatible with stock 883 heads!

- Andrews V2/N2 - Excellent alternative to the Jacckhammer 570 cams when using stock 883 heads. Also an excellent choice for 1988-2003 XL1200's with the stock 9:1 compression ratio. Strong on the bottom to middle in particular. Recommended compression ratio of 9:1 to 10:1.

- Andrews V4/N4 - Our favorite bolt-in grind for the 1986-2003 generation of XL's. Original equipment on many Buells. Ideal compression ratio of 9.5:1 to 10.5:1. Broad powerband and can pull to 6800rpm

with good heads and pipe. Easy on the valvetrain. An excellent match for our Impact head porting service on this generation of heads. Recommended compression ratio of 10:1 to 10.5:1. Not compatible with stock 883 heads!

- Feuling 505/515 - An excellent alternative to the Andrews N4 when using stock 883 heads. The low TDC lifts will

not create piston-to-valve clearance issues as sometimes happens with the N4's paired with stock 883 heads. Broad powerband and can pull to 6800rpm with good heads and pipe. Recommended compression ratio of 10:1 to 10.5:1. 2000+ pinion gear required when used in 1991-1999 models.

- HAMMER Impact 560 - An amazingly versatile grind. Bolt-in for the late model 1200's. Proven to add as much as 14hp to a stage 1 EFI 1200. Also a part of the 100+hp 883-1275

conversion package.

Similar intake timing as the N4 above but with additional lift to take advantage of the better hardware in the later heads and more

overlap to take advantage of good exhaust systems.

Ideal compression ratio of 10:1 to 10.5:1. Broad powerband and can pull to 7400rpm with good heads and pipe. Easy on the valvetrain and designed for quiet operation. Smaller than stock base circle to simplify installation.

An excellent match for our Impact head porting service on the latest generation of heads. Not compatible with stock 883 heads!

- Red Shift 585 - Great street cam for 88 inchers or

race 1275's. 10.5:1 to 12:1 ideal compression ratio. Easy on the valvetrain. Low TDC lifts for easy

setup. Cam box clearancing and long tappet flats are generally required, as well as lobe clearancing for pinion race. Excellent match for Smash or Sledge head service

with heavy duty valvetrain pieces. Broad powerband up to 7400+ rpm.

- HAMMER Crush 600 - Great street cam for 88 inchers or hot 1275's. 10.5:1 to 11:1 ideal compression ratio. Easy on the valvetrain and designed for quiet operation.

Requires pistons with large valve pockets. Small base circle for easy installation. Excellent match for CRUSH head service but will work well with Smash or Sledge as well.

Designed to be compatible with our PAC Alloy beehive spring pack when used with 7mm stems or our .650 lift Sledge Hammer spring pack with 5/16" stems.

- HAMMER Sledge 660 - High lift grind for hot street or race applications in 88-100ci engines. Works best in big valve heads to take advantage of the lift. 10.5.:1 to

12:1 ideal compression ratio.

Easy on the valvetrain. A lot of overlap makes it sensitive to the exhaust system. Roller rockers mandatory. Check valve to piston carefully. Cam box clearancing and long

tappet flats are required, as well as lobe clearancing for pinion race on most motors. Excellent match for Sledge head service on street applications. Broad powerband up to 7200+ rpm.

- Red Shift 729V2 - Race grind for 88 inches and bigger. Works best in big valve heads to take advantage of the lift. 12.:1 to 14:1 ideal compression ratio.

A lot of overlap makes it sensitive to the exhaust system. Check valve to piston carefully. Roller rockers required. Cam box clearancing and long tappet flats are absolutely

required, as well as lobe clearancing for pinion race on most motors. Excellent match for Sledge head service on race applications. Broad powerband up to 7500+ rpm.

The tooth pitch was changed on the pinion & #2 drive gears starting in 2000

91-99 style shown on left, 2000-Up shown on right

A note on pinion gears: Starting in 2000, HD went to a new, finer pitch on the pinion gear and the matching drive gear on the #2 cam. This change was

then made on all the gear connections for 2001. Note that some cam grinds are only available in one series or the other. To retrofit 2000-up cams to 1991-1999 motors,

update the pinion gear (available below). Likewise, to put 1991-1999 cams into 2000-Up models, back date the pinion gear. Alternatively, if you have a press,

read this for instructions on how to move your drive gear from one set of cams to another.

"Bolt-In" Cams: "Bolt-In" means that the cam manufacturer believes the cams will go into your motor with the rest of the parts all stock, and generally

without any clearancing work as well. In other words, they install just like a set of the original cams. While bolt-in cams are convenient, if you restrict yourself

to bolt-in cams you're leaving power on the table, particularly if you've done head work. Head porting allows the head to flow more air at lifts beyond what

the stock cams provide. Bolt-in cams also typically don't have a lot of overlap, to keep TDC lifts and the associated issues down, so they generally can't

reap the benefits of a high overlap grind the area of exhaust augmented intake flow.

XL Cams from HAMMER PERFORMANCE

HAMMER PERFORMANCE is proud to announce cams of our own design. We put a great deal of work into coming up with these cams,

paying particular attention to torque and power production, ease of installation, and quiet operation. Although they're optimized for

HAMMER PERFORMANCE CNC Head Porting, they work well in other applications too. See the description above for each grind.

Click the thumbnails below for some of the dyno results from these cams.

JACKHAMMER 570 vs. Stock "W" cams

|

IMPACT 560 vs. SE .536 cams

|

CRUSH 600 vs. SE .536 cams

|

SLEDGE 660 vs. W68S&RS643

|

Note: the SLEDGE 660 cams are for installation in 1991-2005 motors only. Installation into a 2000-2005 motor requires backdating the pinion gear to the coarse tooth pitch,

available below.

Note 2: SLEDGE 660 cams will be available approximately late March 2013

| HAMMER PERFORMANCE Cams |

| Cam Grind |

Timing |

.053 Duration |

TDC Lift |

Max Lift |

Add to Cart |

JACKHAMMER 570

Bolt-in for 04-up XL1200 models |

I:28/32

E:42/28 |

I:240

E:250 |

I:.228

E:.220 |

I:.570

E:.570 |

|

IMPACT 560

Bolt-in for 04-up XL1200

Also available & bolt-in for 2003-2007 Buell XB models |

I:28/48

E:58/28 |

I:256

E:266 |

I:.228

E:.220 |

I:.560

E:.560 |

|

| CRUSH 600 |

I:30/54

E:60/30 |

I:264

E:270 |

I:.244

E:.236 |

I:.600

E:.600 |

|

SLEDGE 660

for 1986-2005 models only

2000-2005 models require backdating to 1991-1999 coarse tooth pinion gear |

I:30/60

E:64/30 |

I:270

E:274 |

I:.248

E:.236 |

I:.660

E:.660 |

|

XL Cams from Andrews

Andrews is the biggest name in XL cams and they offer the most grinds. We've had great success with both their street and race cams

| Andrews Cams |

| Cam Grind |

Timing |

.053 Duration |

TDC Lift |

Max Lift |

Add to Cart |

N2/V2

Bolt-in |

I:22/38

E:46/18 |

I:240

E:244 |

I:.180

E:.155 |

I:.465

E:.440 |

|

N3

Bolt-in |

I:17/33

E:43/11 |

I:230

E:234 |

I:.181

E:.134 |

I:.465

E:.482 |

|

N4/V4

Bolt-in |

I:30/46

E:52/24 |

I:256

E:256 |

I:.216

E:.189 |

I:.490

E:.490 |

|

| N6/V6 |

I:34/50

E:56/28 |

I:264

E:264 |

I:.241

E:.212 |

I:.500

E:.500 |

|

| N8/V8 |

I:32/44

E:56/28 |

I:256

E:264 |

I:.226

E:.212 |

I:.490

E:.500 |

|

| N9/V9 |

I:33/53

E:53/33 |

I:266

E:266 |

I:.240

E:.240 |

I:.555

E:.555 |

|

| BV/NV |

I:35/59

E:59/35 |

I:274

E:274 |

I:.260

E:.260 |

I:.590

E:.590 |

|

| N80/V80 |

I:32/60

E:626/30 |

I:272

E:276 |

I:.264

E:.244 |

I:.600

E:.600 |

|

| N83/V83 |

I:32/64

E:70/30 |

I:276

E:280 |

I:.267

E:.248 |

I:.630

E:.630 |

|

| N87/V87 |

I:34/70

E:76/32 |

I:284

E:288 |

I:.283

E:.269 |

I:.670

E:.670 |

|

XL Cams from Feuling

The Feuling 505/515 cams are our choice when you're using stock or mildly modified 883 heads and you want a mid range to top end type power band.

883 heads have longer valves than 1200 valves, to reach the shallower chamber and make the valves fit within the 3 inch diameter chamber.

This puts the valves closer to the pistons to begin with as compared to 1200 heads, which means it's easier to run into issues with piston to valve clearance.

Basically, anytime you use cams with a TDC lift figure of more than about .200 on either valve, with stock 883 heads, you're taking a chance.

The low TDC lifts of the Feuling 505/515 ensures you'll have no issues with piston-to-valve clearance when used with 883 heads. The 48 degree intake

valve close timing will deliver a mid range to top end power band similar to the N4's, but without the high TDC lifts and associated risk. Thse cams are well matched to a

compression ratio in the range of 10:1 to 10.5:1.

The Feuling 580 cams fill a need when you need a high lift, late IVC (meaning high rpm) set of cams with reduced base circles to reduce cam box and tappet pin clearance issues, and low TDC lifts to simplify head setup. They work best with a compression ratio of 11:1 to 11.5:1. These are not bolt-ins, they require the heads to be

set up for the high lift (coil bind and retainer-to-guide-seal clearance). The low TDC lifts however lets you avoid issues with piston-to-valve clearance.

To use either of these cam sets in a 1991-1999 model, you will need to either update your pinion gear to the 2000+ version

or move your #2 drive gear from your old cams to your new ones.

| Feuling Cams |

| Cam Grind |

Timing |

.053 Duration |

TDC Lift |

Max Lift |

Add to Cart |

505/515

Bolt-in

Fits 2000-2022 XL's

See note above for 1991-1999 fitment |

I:11/48

E:53/15 |

I:239

E:248 |

I:.137

E:.150 |

I:.505

E:.515 |

Fits 2000-2022 XL models

$459.95

|

580

NOT bolt-ins: Head setup and cam box clearancing required

Fits 2000-2022 XL's

See note above for 1991-1999 fitment |

I:21/57

E:67/21 |

I:258

E:268 |

I:.193

E:.180 |

I:.580

E:.580 |

Fits 2000-2022 XL models

$459.95

|

XL Cams from Red Shift

Red Shift Cams have a unique feature: they can be made right on your existing cam gears. This is especially beneficial in 1991-1999 models which came from the factory

with fitted cams to reduce noise. By having Red Shift lobes put on your cams, you maintain that factory fit and gear quietness.

| Red Shift Cams |

| Cam Grind |

Timing |

.053 Duration |

TDC Lift |

Max Lift |

Add to Cart |

| 567V2 |

I:24/49

E:54/19 |

I:253

E:253 |

I:.211

E:.172 |

I:.567

E:.567 |

|

575V2

Bolt-in for 2004-Up |

I:26/38

E:44/20 |

I:244

E:244 |

I:.204

E:.172 |

I:.575

E:.575 |

|

| 585V2 |

I:22/59

E:66/13 |

I:261

E:259 |

I:.183

E:.139 |

I:.583

E:.583 |

|

| 630/585V2 |

I:26/40

E:59/21 |

I:246

E:260 |

I:.224

E:.181 |

I:.630

E:.583 |

|

| 643V2 |

I:28/62

E:71/19 |

I:270

E:270 |

I:.235

E:.172 |

I:.643

E:.643 |

|

| 729V2 |

I:34/65

E:71/28 |

I:279

E:279 |

I:.279

E:.228 |

I:.729

E:.729 |

|

| 790V2 |

I:36/66

E:66/36 |

I:282

E:282 |

I:.282

E:.280 |

I:.790

E:.790 |

|

Note: Outright Red Shift cams are all 1991-1999 Style.

To use in a 2000-Up motor, back date your pinion gear (available here)

|

Pinion Gears

Updating or backdating cams in your XL engine? Be sure to

match your pinion gear to your cams. We carry both the

1991-1999 style in 5 different sizes as well as the 2000-Up

style "high contact ratio". Either style will bolt right

into a 1991-present engine, which allows you to use late

model cams in earlier engines and vice-versa.

We also carry pinion gears for 1986-1987 models. These

gears are splined and will not fit the pinion shaft of any

other years.

Pinion gears for 1988-1990 models are no longer available, sorry.

If you're not sure what size to use, get the yellow

(smallest) gear. A little clatter won't hurt anything but

gears that are too tight will cause localized tooth heating

and failure.

Tech Tip: Never tighten or loosen the pinion nut by holding the flywheel assembly on the opposite side, by any method, including holding

the rear brake with the trans in gear.

The flywheel assembly is not made to hold torque twisting through it's crankpin and you can easily knock it out of true, necessitating a full tear down to repair.

Instead, use one of our pinion locking tools to properly hold the pinion shaft in place.

UPDATE: Unfortunately, as of February 2022, 1991-1999 pinion gears are no longer available

| 1991-Present XL Pinion Gear |

|

1986-1987 XL Pinion Gear

(Splined) |

|

|

Bronze Oil Pump Drive Gears

Sportster and Buell engines are notorious for wearing the oil pump drive gear on the pinion shaft. Pinion shaft runout causes this. HAMMER PERFORMANCE has the

solution, though, a bronze oil pump drive gear that greatly reduces wear in this critical area. Check your stock drive gear; if the teeth are getting sharp on one side,

it's time to get one of these. If you're into the cam box anyway for a cam change, it's cheap insurance.

Tech Tip: Never tighten or loosen the pinion nut by holding the flywheel assembly on the opposite side, by any method, including holding

the rear brake with the trans in gear.

The flywheel assembly is not made to hold torque twisting through it's crankpin and you can easily knock it out of true, necessitating a full tear down to repair.

Instead, use one of our pinion locking tools to properly hold the pinion shaft in place.

Bronze Oil Pump Drive Gear - $128.99

Fits 1988-Present Sportster and Buell |

|

|

|

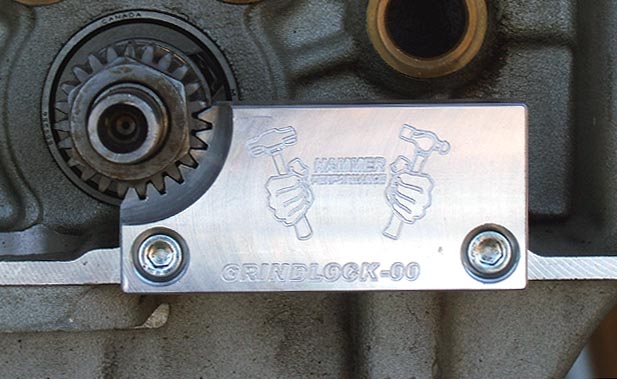

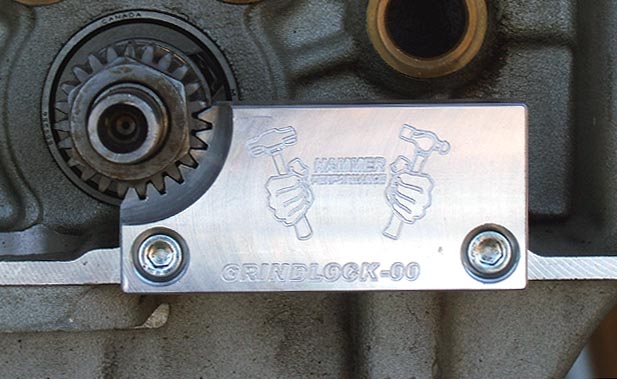

Pinion Gear Locking Tools

If you're changing the pinion gear and/or the oil pump drive gear, you need this tool! If you hold the crank still from the other side of the

assembly - the primary side, or by putting the bike in gear and holding the brake - you apply twisting force through the crank pin, and the crank pin is not

designed to resist much twisting force. You run the very real risk of knocking the crank out of true, which requires a full tear-down to fix.

Don't take the risk, get yourself one of our exclusive Grindlock pinion locking tools. We work on these bikes all the time, and frankly the other offerings

on the market for this function frustrated us with weak teeth that liked to push away from the pinion gear. The Grindlock design solves that problem. It also engages for the

full depth of the pinion gear for maximum strength.

Click Here for Instructions on Using this Tool. It's not always obvious exactly how it goes onto the gear and some people mistakenly assume we

sent them the wrong tool or it's somehow defective. The instructions clear this up.

GrindLock Pinion Locking Tool for XL models

Also works on 1991-2002 Buell models except Blast |

|

|

Lifters

High lift cams and high rpm's place special demands on your lifters. At HAMMER PERFORMANCE, we carry quality lifters from S&S and Comp Cams.

S&S Lifters, Clockwise from Upper Left: Premium Lifters for 00+ XL, High Performance Lifters for 00+ XL,

High Performance Lifters for 86-90 XL, High Performance Lifters for 91-99 XL

For 2000+ Sportsters, as well as all Twin Cam and M8 applications, our recommended lifter is the S&S "Precision". New for 2020, these lifters replace the previous

"Premium" and "High Performance" products. They're offered at a better price than the previous Premiums, and retain all the same advantages and features.

So while the stock lifters are adequate in most applications, if you're looking for an upgrade for your 2000+ Sportster, these are what we recommend.

Features of the S&S Precision lifters include:

- Reduced valve train noise from start up to shut down

- Close tolerances for low leak down rates

- Fast pump up and superior high rpm performance

For 1991-1999 Sportsters, our preferred lifter is the Comp Cams/V-Thunder "Hy-Rev". This is a quality piece designed to work well at high rpm.

Features of the Comp Cams V-Thunder Hy-Rev lifters include:

- Features an oil metering design that provides uniform metering throughout the entire rpm range

- Rollers and axles are manufactured from high-carbon/ chromium bearing-quality steel, which is through-hardened for improved wear and load-carrying capability, and the pushrod seat is carbo-nitrided

- Each unit is 100% tested for proper function

- Internal hydraulic check valve, which allows for higher rpm

For 1986-1990 Sportsters (and Evolution Big Twins), we recommend and offer the S&S "High Performance" lifter.

Features of the S&S High Performance lifters include:

- Redesigned plunger assembly better withstands forces associated with heavy-duty valve springs and cams typically used in high-performance applications

- Revised metering device precisely controls oil delivery to top end, ensuring rapid lifter pump-up and reducing possibility of oil starvation to bottom end

- Each lifter body and plunger assembly is selective-fit and tested to ensure correct operation

- Larger inner bearing race reduces stresses to increase axle, bearing and roller life. The S&S inner bearing race is .123" larger in diameter than the "raceless" roller axles currently used by some manufacturers.

- Improved inner race-roller design allows use of more and larger bearings to increase load – carrying surface area, further reducing stress and wear in the critical roller area.

| Lifters |

| Application |

Lifter |

Price |

|

| 2000+ XL |

S&S Precision |

$279.95

Set of Four |

|

| 1991-1999 XL |

Comp Cams Hy-Rev |

$100.95

Set of Four |

|

| 1986-1990 XL |

S&S High Performance |

$304.95-$325.95

Set of Four |

|

|

Sledge Hammer Pushrods

Strong, stiff pushrods are essential in a high performance engine. Sledge Hammer pushrods are the ultimate in heavy duty, featuring .065" or .083" wall heat treated chrome

moly construction and "Mae West" ends for high lift cams. Available in adjustable or non-adjustable styles.

If you're planning to run more than 240lbs of valve spring seat pressure, choose the .083" wall pushrods. This much pressure is really only for all-out race motors

though. High performance street applications and many race applications will be better off with the .065" wall pushrods.

Tip: a non-adjustable pushrod is stronger than an adjustable pushrod at a given weight. Ideally you should always use a non-adjustable pushrod when using standard hydraulic

lifters and use adjustable pushrods when using HydroSolid or full solid lifters. Read our Tech Tips Article on Pushrod Length for more information.

We stock fixed length pushrods in a length that's .050" shorter than stock because this is a

typical value after head decking and optimizing squish clearance through thinner gaskets. However, if you need some other length, no problem,

we custom make pushrods to your specifications as well.

| Sledge Hammer Pushrods |

| Application |

Type |

1991-2003 XL1200

1995-2002 Buell

(set) |

|

2004-Up XL

2003-2010 Buell

(set) |

|

Custom

(each) |

|

|

Collapsible Pushrod Tube Kits

Don't put up with cheap, leaky collapsible cover kits! Our kits use VW style conical seals at the base to ensure a leak-free connection. The bases themselves are

CNC machined from billet aluminum and look as well as they work.

Note: Kits for 04-Up models utilize the stock pushrod bases and seal system.

Note 2: Kits for 1991-2003 XL and 1995-2002 Buell may require minor clearancing of the lowest cylinder fin.

| Collapsible Pushrod Tube Kit |

|

| Replacement O-Ring and Seal Set |

|

|

Billet Base Kits for Stock Pushrod Tubes

The stock lower pushrod tube retainer on a 1991-2003 Sportster is a cheapo piece of pot metal that bends and distorts, causing leaks.

Replace yours with our Billet Base Kit to solve this problem. They look great, too! Precision CNC machined in-house out of T6061 billet aluminum.

Each kit comes with two bases, the upper o-rings, the lower seals, and four stainless steel screws.

Billet Pushrod Tube Base Kit - $49.95

Fits 1991-2003 Sportster

or 1991-2002 Buell (except Blast) |

|

Tips for Installing the Billet Pushrod Bases:

Although the undersides of the billet bases are dimensionally the same as the factory pot-metal rings, you're installing two at once and this can make it a little more challenging.

Here are the techniques we use that have proven to be successful:

- Have your cylinder heads already installed, and put the upper o-rings into their pockets in the undersides of the heads. Lube the inside of those o-rings with a little grease

- Remove the roll pins in the case deck that are used to align the factory pot-metal o-rings. You can just pull them out with a pair of pliers, they come out easily.

- Make sure the case deck is clean and free of debris or scratches.

- Clean any grease or oil residue from the underside of the billet base. This is especially important in the areas where the seal will be contacting it. Use brake parts cleaner or a similar solvent and wipe with a paper towel.

- Likewise clean the seal in the same manner in all areas where it will contact the billet base. The idea here is to have everything squeaky clean so that absolutely nothing that will make it easier for the seals to slide out of the base.

- Put two seals into position in the underside of a billet base. Some people even put a few drops of super glue onto each seal to help hold them in place in the base, but this generally isn't necessary if you've got both squeaky clean.

- Now that the seals are in place in the underside of the base, lightly grease the inside of each seal (the area that will contact the pushrod cover), being careful not to get any grease anywhere else on the seal or base.

- So in other words, you want the seal squeaky clean everywhere it contacts the billet base, but lubricated where it will contact the pushrod cover.

- Stand up both pushrod covers side by side

- Carefully slide the base/seal assembly over the tops of the pushrod covers, down the covers, down over the thick part of the covers, and down to about an inch from the bottom. Make sure the seals are still in place in the underside of the billet base.

- Carefully insert the tops of the pushrod covers up into the pockets in the underside of the head, through the o-rings which are already sitting in their pockets.

- Swing the bottom of the assembly into place over the lifters.

- Push the base down onto the case deck and HOLD PRESSURE ON THE BASE.

- WITHOUT RELEASING THE PRESSURE ON THE BASE, install both screws and snug them down. Once they're snugged down you can remove the pressure on the base and finish tightening the screws.

- The key here is to never let the seal pop out of the bottom of the billet base. If it pops out during this process, it'll get sandwiched between the billet base and the case deck and it'll leak for sure. But if it stays in place, it'll seal fine.

- Repeat the process for the other cylinder.

|

Rocker Arms

At HAMMER PERFORMANCE, we've seen just about every brand of rocker arms have a failure at one time or another, except for one in particular: S&S! So of course,

those are the ones we carry! These rockers are forged from 8620 steel alloy, heat treated and shot peened. They use 3/4" long bushings instead of the 1/2" bushings found in other rocker arms. The net result is the finest set of rocker arms on the market. We've subjected these roller rockers to some extreme abuse in our Bonneville motors, with spring pressures north of 270lbs on the seat, .785 lift cams, and 7500rpm, for miles at a time, over and over, and we've yet to break one. We highly recommend these roller rockers for any application with valve lifts over .585 and/or spring pressures greater than 180lbs on the seat. Available in stock 1.625 ratio or high lift 1.725 ratio.

We also offer S&S stock replacement rocker arms. These do not have roller tips, but they are fine for cams up to .585 lift. As with the roller versions, these use 3/4" long bushings and are forged from 8620 alloy. The tips are induction-hardened for long life.

Note that high ratio rockers require proper setup of valvetrain geometry, they are not a bolt-on.

S&S Rocker Arms

all Evolution 80, XL, Buell, Twin Cam

Set of 4 |

|

| Rocker Arm Shafts, Set of 4 - $50.95 |

|

|

Sledge Hammer Valves, Springs, Guides and Seals

For the Ultimate in Strength and Durability

The Sledge Hammer series of valvetrain components is our heavy-duty line. These are the parts that can take the extreme abuse of racing, and they're recommended for

hot street applications as well.

Sledge Hammer Stainless Steel Valves

These valves were developed for the most extreme applications in NASCAR and other race venues where durability is the name of the game. They can withstand the punishment of high rpm,

multiple stages of nitrous, turbocharged, and even blown fuel applications. We use these same valves in our 200+mph nitro burning Bonneville race bike. You simply cannot buy a better valve

for your Harley Davidson performance engine. All valves use the most advanced stainless alloy and are swirl polished for maximum flow. 5/16" Stems.

|

| Sledge Hammer 5/16" Stem Competition Valves |

| Application |

Choose Size |

Intake - 86-03 XL1200, 99-04 Twin Cam,

& all Evo Big Twin (sold each) |

|

Exhaust- 86-03 XL1200, 99-04 Twin Cam,

& all Evo Big Twin (sold each) |

|

Intake - KPMI

86-03 XL883

(sold each) |

|

Exhaust - KPMI

86-03 XL883

(sold each) |

|

Sledge Hammer Competition Valve Springs

Sledge Hammer valve springs are manufactured on state-of-the-art equipment out of the finest grade chrome silicon steel. They are then heat treated and

stress relieved, which dramatically improves valve spring life. All springs are subject to strict quality screenings including cycle testing to ensure

consistency from batch to batch. The bottom line is that these springs provide the stability needed for high lift, high rpm applications and the durability

you need for years of trouble free service. We use these springs in our all-out race motors as well as our hot street motors.

Each Sledge Hammer valve spring is a dual spring assembly with a damper to control harmonics

Each kit includes four springs, four titanium retainers, eight 10 degree valve locks, and four spring seat locaters.

Sledge Hammer Competition Valve Springs

Specifications |

| Application |

O.D. |

Seat Pressure |

Coil Bind

Height |

Rate

lbs/inch |

| Up to .600 Lift |

1.440" |

175lbs @1.810" |

1.160" |

320 |

| Up to .650 Lift |

1.530" |

135lbs @1.875" |

1.160" |

400 |

| Up to .700 Lift |

1.550" |

215lbs @1.950" |

1.170" |

460 |

Sledge Hammer Competition Valve Spring Kit

Includes Springs, Ti Retainers, Keepers,

& Seat Locaters for 4 Valves |

|

Sledge Hammer 10 Degree Valve Keepers

for 5/16 Valve Stems - Set of 8 for 4 Valves

Compatible with the retainers in the above kits

|

|

Note: HAMMER PERFORMANCE recommends using only new keepers whenever a cylinder head is assembled.

Sledge Hammer Valve Guides & Seals

Being cylinder head porters, we're very opinionated about the parts that go into a cylinder head. We've used valve guides from every major manufacturer,

and these pieces from AV&V are the best we've ever found. They feature:

A viton o-ring to prevent oil from passing between the guide and the head A step to ensure positive depth placement They're shorter on the top side to give room for high lift cams A .531 diameter seal area with grooves to prevent the seals from falling off Aerodynamically shaped ends for maximum flow, optimized separately for intake and exhaust The best bronze alloy that allows a tight fit without fear of sticking

Please note that all of these guides come unfinished and must be reamed or honed to fit

|

Equally important to the guide is the guide seal itself.

AV&V viton guide seals resist temperatures 50 degrees higher than most viton seals. These seals

work great and eliminate one more potential source of issues. That's the kind of parts we like to use!

We offer 5/16 stem diameter guide seals both in the .531 diameter to match the guides we sell, as well as in the .421 diameter to fit the stock

guides as found on 86-03 XL's, 99-04

Twin Cams, and all Evo Big Twins.

|

Intake Guide

5/16 Stem for 86-03 XL, 99-04 Twin Cam,

& all Evo Big Twin (sold each)

Can be fitted to later heads as well |

|

Exhaust Guide

5/16 Stem for 86-03 XL, 99-04 Twin Cam,

& all Evo Big Twin (sold each)

Can be fitted to later heads as well |

|

Guide Seal

5/16 Stem - Set of 4 |

|

|

Striker Valves, Springs, Guides and Seals

Strong & Lightweight Valvetrain Pieces for Street Performance

The Striker series of valvetrain components is for street performance applications. They feature ultra light weight 7mm stem valves and beehive springs.

Striker 7mm Stem Stainless Steel Valves

These top quality valves feature the same advanced alloys

as our Sledge Hammer valves above, but are made with ultra

lightweight 7mm stems.

Strong, durable, and high flowing, these valves are

perfectly suited to street performance applications with up

to .600 valve lift and 175lbs spring pressure on the seat.

For more demanding applications, use Sledge Hammer valves.

All of the 7mm Stem Striker valves below have triple grooves

compatible with factory keepers and retainers, except part

numbers F0320, F0320M, and F0318 which require keepers

K10062 sold below.

|

| 7mm Stem Performance Valves |

| Application |

Choose Size |

Intake - 04-Up XL1200, 05-Up Twin Cam

& all Buell XB (sold each) |

|

Exhaust- 04-Up XL1200, 05-Up Twin Cam

& all Buell XB (sold each) |

|

Intake - 04-Up XL883

(sold each)

See Note 2 Below |

|

Exhaust - 04-Up XL883

(sold each)

See Note 2 Below |

|

Note: Part numbers F0320, F0320M, F0320MM, and F0318 use a single keeper groove that is not compatible with the factory 7mm locks. Use locks K10062 sold below

Note 2: Proper installation of conversion valves F0300M and F0302M requires the enlarging of the 883 combustion chambers. When using these valves, Hammer Performance recommends using flat top pistons

for proper compression ratio. For 7mm conversion valves that work with dished pistons, use valves #20-20550 and #20-20555

|

Striker Beehive Valve Springs for 7mm Stem Valves

Beehive springs offer certain advantages over conventional dual or triple spring assemblies, particularly in the area of reduced weight at the top end (which has the most movement)

and improved harmonics. They also eliminate the need for rocker box clearancing

for the springs in HD applications.

The downside to a beehive is that for a given combination of seat pressure and installed height, less travel is available. Essentially, since there's only one spring,

the spring wire has to be made thicker to achieve a given seat pressure, and that sacrifices travel. Therefore, in HD applications the beehive style springs are

best suited for moderate lift and pressure applications. This makes them a perfect match for 7mm stem valves.

Our base level beehive spring is very well priced and has been proven suitable for most cam grinds up to .550 lift and rpm's up to 6900. This spring pack uses lightweight steel retainers.

For higher lifts and rpm we also offer a .650 lift spring pack from AV&V. This is a high quality spring pack with chrome moly retainers

Striker Performance Valve Springs

Specifications |

| Application |

Seat Pressure |

Coil Bind

Height |

Rate

lbs/inch |

| Up to .550 Lift |

130lbs. @1.850" |

|

|

| Up to .650 Lift |

178lbs. @1.860" |

1.150" |

318 |

Striker Performance Valve Spring Kit 7mm

Includes Beehive Springs, Retainers,

& Keepers for 4 Valves

.650 lift set also includes

seat locators for high lift

applications. Be sure to use

the matching guide seals

offered below.

|

|

Striker Performance Valve Spring Kit 5/16

Includes Beehive Springs, Retainers,

& Keepers for 4 Valves

and seat locators

|

|

Striker Performance Valve Keepers

for 7mm Valve Stems - Set of 8 for 4 Valves

Compatible with the retainers in the above .550 lift spring kits

|

|

Note: HAMMER PERFORMANCE recommends using only new keepers whenever a cylinder head is assembled.

Striker Valve Guides & Seals

As with the 5/16 Sledge Hammer series, we've found the AV&V guides to be the best available, for

most of the same reasons:

A viton o-ring to prevent oil from passing between the guide and the head A step to ensure positive depth placement Aerodynamically shaped ends for maximum flow, optimized separately for intake and exhaust The best bronze alloy that allows a tight fit without fear of sticking

The only real difference between these and the 5/16 pieces, other than the stem diameter, is the way the top is done. These guides use a .562" diameter

top like the factory guides on 2004-Up XL's and 2005-Up Twin Cams, which means the seals for these guides are fully compatible with the stock guides as well.

Please note that all of these guides come unfinished and must be reamed or honed to fit

|

The 7mm stem guide seals feature the same high-temperature viton material found on the 5/16 stem guide seals. They are also compatible with both the AV&V guides above as well as the OEM guides.

This larger .562 i.d. 7mm guide seal, which HD introduced in 2004 on XL's and 2005 on Twin Cams, was a design improvement on their previous generation of

.431 i.d. 5/16 stem guide seals. The larger diameter

adds stability, plus the way the guide seal is held in place by the spring seat locater is a nice design that keeps the guide seal in place and stable.

The design has a downside, however, in that shimming the

valve springs moves the seal upward, which reduces retainer

to seal clearance and pushes the seal up on the guide. The

tall guide protrusion above the head surface also limits

maximum lift. Applications above .600 of valve lift should use the conventional design seals (second in the pull-down below)

with separate seat locators.

|

Intake Guide

7mm Stem for 04-Up XL, 05-Up Twin Cam

(sold each)

Can be fitted to earlier heads as well |

|

Exhaust Guide

7mm Stem for 04-Up XL, 05-Up Twin Cam

(sold each)

Can be fitted to earlier heads as well |

|

Guide Seal

7mm Stem - Set of 4 |

|

|

|

|

|

|

|

|